Directly print your parts and assemblies with LFAM thermoplastic composites. Avoid tooling!

Advantages to 3D Printing Parts & Structures

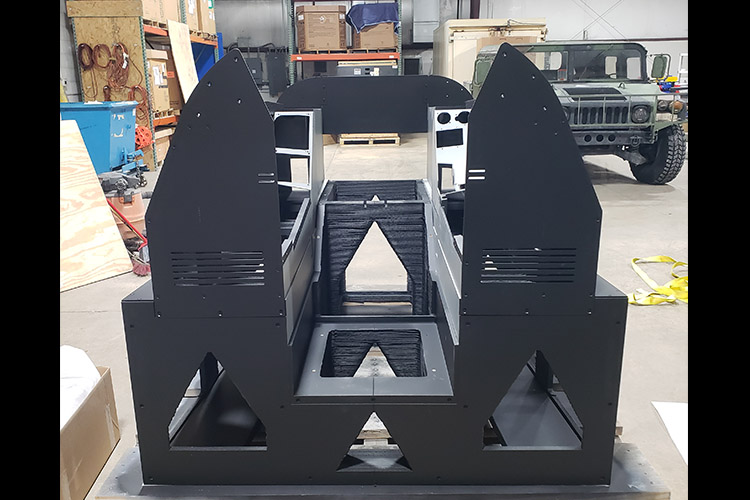

Major Part Consolidation

Design for LFAM, reduce part count.

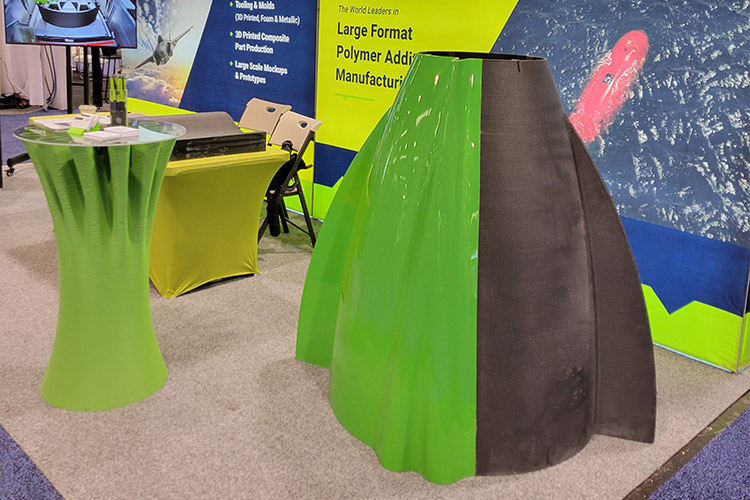

Tool-less Solution

No mold/tool needed to produce parts.

Easy Design Modifications

Changes can be made quickly and inexpensively.

While most of the things we 3D print are a tool or mold, we have found outstanding opportunities for 3D printing parts themselves, avoiding tooling altogether! This approach allows for continual customization on your products as you are not beholden to the design from a mold. Plus, parts can typically printed in the time in takes to pull a mold off the shelf and prep it for layup.

We’re replacing conventional part fabrication with a tool-less, direct solution!